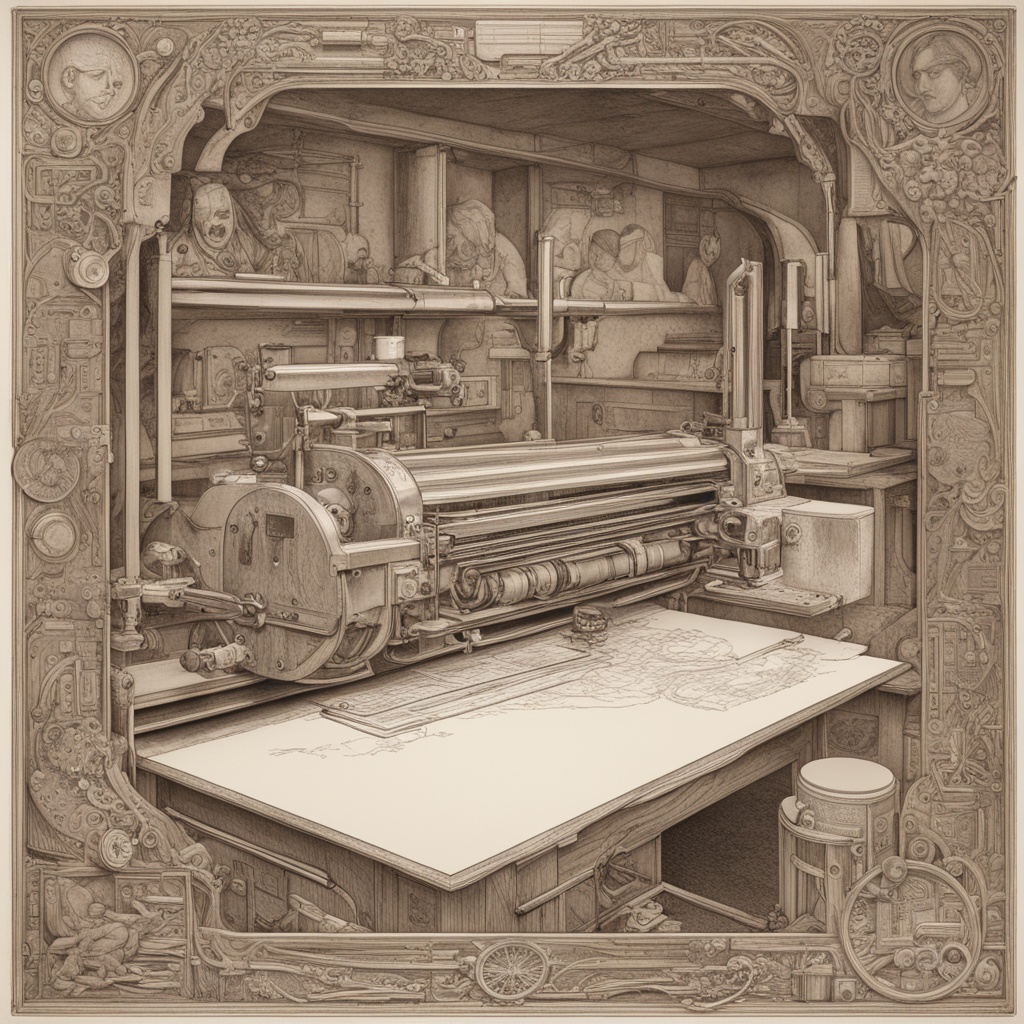

Exploring Laser Engraving Programs: Precision, Efficiency, and Creativity

Laser engraving has revolutionized industries ranging from manufacturing to artistry, offering unparalleled precision and versatility. At the heart of this innovation are laser engraving programs, which enable users to design, customize, and execute intricate patterns with ease. Whether you’re working in metal, wood, plastic, or other materials, laser engraving programs provide the tools needed to bring your ideas to life. In this article, we’ll delve into the world of laser engraving programs, exploring their applications, benefits, and how they empower creators across various fields.

What Are Laser Engraving Programs?

Laser engraving programs are software solutions designed to control laser engravers. These programs allow users to create detailed designs, adjust settings, and send instructions to the laser machine for. The best laser engraving programs offer intuitive interfaces, making it easy for both beginners and professionals to achieve exceptional results. They often include features like vector graphics support, raster image processing, and advanced editing tools.

One of the most popular options in the market is the Laserhawk LH3-9 fiber laser engraver, which comes with its own set of laser engraving programs optimized for metal and other materials. These programs ensure high precision and reliability, making them a favorite among manufacturers and artists alike.

Applications of Laser Engraving

Laser engraving is incredibly versatile, with applications spanning numerous industries:

- Jewelry Making: Creating intricate designs on metals like gold, silver, and platinum.

- Metalworking: Engraving serial numbers, logos, or patterns on tools, machinery, and consumer goods.

- Furniture Design: Adding decorative elements to wooden surfaces with precision.

- Electronics: Marking circuit boards or components with permanent identifiers.

- Crafts and Art: Producing custom designs for items like name tags, plaques, and signage.

The versatility of laser engraving programs makes them indispensable in modern manufacturing and creative processes. With the right software, users can unlock the full potential of their laser engraver machines.

Key Features of Laser Engraving Programs

High-quality laser engraving programs come packed with features that enhance productivity and creativity:

- Design Tools: Advanced tools for creating or importing designs, including vector graphics support.

- Material Settings: Predefined settings for different materials like metal, wood, and plastic to ensure optimal engraving results.

- Speed Control: Adjustable laser speed settings to balance between precision and efficiency.

- Preview Functionality: Real-time preview of the engraving process to avoid mistakes before execution.

- Batch Processing: The ability to queue multiple jobs for continuous operation, saving time in high-volume production environments.

These features make laser engraving programs not just tools but complete solutions for modern creators. For instance, the Laserhawk LH3-9 laser engraver machine is equipped with cutting-edge software that streamlines workflows and ensures consistent quality across projects.

Benefits of Using Laser Engraving Programs

The adoption of laser engraving programs brings numerous benefits to businesses and individuals alike:

- Precision: Achieve exact, repeatable results with minimal error margins.

- Speed: Process large quantities of items quickly while maintaining high quality.

- Customization: Create unique designs tailored to specific needs or preferences.

- Cost-Effectiveness: Reduce waste and minimize material costs through precise engraving.

- Versatility: Work with a wide range of materials and applications, from industrial parts to artistic creations.

These advantages make laser engraving programs an essential investment for anyone looking to enhance their production capabilities or creative output. Whether you’re running a small workshop or managing a large-scale manufacturing operation, these tools can significantly improve efficiency and quality.

Frequently Asked Questions About Laser Engraving Programs

If you’re new to laser engraving, here are some common questions and answers:

- What materials can I engrave with these programs? Most laser engraving programs support a variety of materials, including metal, wood, plastic, glass, and leather. The Laserhawk LH3-9 machine, for example, is optimized for metal engraving but can also handle other materials with the right settings.

- Can I use my own designs? Absolutely! Many laser engraving programs allow you to import your own vector graphics or raster images, giving you full creative control over your projects.

- How easy is it to learn these programs? Most modern laser engraving programs are designed with user-friendliness in mind. With a short learning curve, even newcomers can master the basics quickly.

- Can I edit designs on the fly? Yes, many programs offer real-time editing and preview features, allowing you to make adjustments without interrupting the engraving process.

By addressing these common concerns, laser engraving programs like those used with the Laserhawk LH3-9 ensure a smooth and enjoyable experience for users of all skill levels.

Choosing the Right Laser Engraving Program

Selecting the right laser engraving program depends on your specific needs and goals. Consider factors like:

- Compatibility: Ensure the software is compatible with your laser engraver machine.

- User Interface: A user-friendly interface can save time and reduce frustration, especially for those who are not tech-savvy.

- Features: Look for programs that offer the tools you need, such as design customization, batch processing, and material-specific settings.

- Support: Choose a program with reliable customer support in case you encounter any issues.

If you’re looking for a comprehensive solution, the Laserhawk LH3-9 laser engraver machine paired with its dedicated software is an excellent choice. It combines powerful features with ease of use, making it ideal for both small-scale projects and large production runs.

Tips for Maximizing Laser Engraving Program Efficiency

To get the most out of your laser engraving programs:

- Familiarize Yourself with the Software: Spend time exploring the features and settings to unlock its full potential.

- Experiment with Designs: Don’t hesitate to try new patterns and materials to discover innovative possibilities.

- Optimize Settings for Your Material: Adjust laser power, speed, and other parameters based on the material you’re engraving to achieve the best results.

- Plan Ahead: Create detailed designs and test them on scrap materials before committing to your final piece.

- Maintain Your Equipment: Regularly clean and maintain your laser engraver machine to ensure consistent performance.

By following these tips, you can enhance the efficiency and output of your laser engraving projects while minimizing errors and waste.

The Future of Laser Engraving Programs

As technology continues to evolve, so too will laser engraving programs. Future advancements are likely to include:

- AI Integration: Automated design suggestions and optimizations based on your preferences.

- Augmented Reality: Previewing engravings in AR before execution for a more immersive experience.

- Cloud-Based Solutions: Accessing laser engraving programs remotely, enabling collaboration from anywhere in the world.

- Sustainability Features: Tools to reduce material waste and energy consumption during the engraving process.

These innovations promise to make laser engraving even more accessible, efficient, and impactful for creators everywhere. Stay ahead of the curve by investing in high-quality laser engraving programs today!

Conclusion

Laser engraving programs are revolutionizing the way we design, create, and produce items across industries. By offering precision, versatility, and ease of use, these tools empower creators to push the boundaries of their craft. Whether you’re working with metal, wood, or another material, the right laser engraving program can transform your ideas into reality with stunning accuracy.

If you’re ready to take your projects to the next level, consider upgrading to a state-of-the-art laser engraver machine like the Laserhawk LH3-9, complete with its dedicated software. With cutting-edge features and user-friendly design, it’s the perfect choice for creators of all levels. Embrace the future of engraving today and unlock new possibilities for your work!