Exploring the Capabilities of Laser Cutter Metal: Precision and Innovation

Laser technology has revolutionized industries across the globe, offering unparalleled precision and efficiency. Among these advancements, the **laser cutter metal** stands out as a game-changer for businesses and hobbyists alike. This article delves into the world of laser cutting metal, exploring its applications, benefits, and how it can transform your projects. Whether you’re a professional or just starting out, understanding the capabilities of a laser cutter metal is essential for unlocking new possibilities in manufacturing and design.

What Is a Laser Cutter Metal?

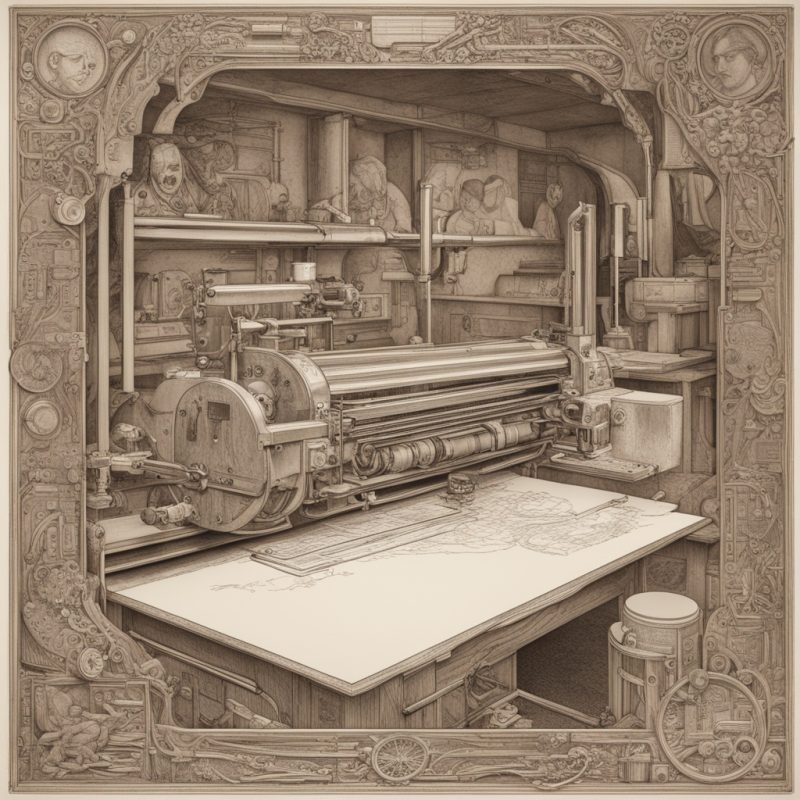

A **laser cutter metal** is a machine designed to cut, engrave, or etch various types of metals with extreme precision. Unlike traditional cutting methods that rely on mechanical tools, laser cutting uses a focused beam of light to melt, burn, or vaporize the material being cut. This process offers several advantages, including high accuracy, speed, and the ability to create intricate designs.

The machine works by directing a laser through mirrors and lenses to focus it onto the surface of the metal. The intense heat generated by the laser melts or vaporizes the metal, creating clean cuts without the need for physical contact. This makes it ideal for delicate materials that might otherwise be damaged by mechanical tools.

Applications of Laser Cutter Metal

The versatility of a **laser cutter metal** makes it applicable across numerous industries. Some common uses include:

- Cutting intricate shapes and patterns in sheet metal

- Engraving logos, text, or designs onto metal surfaces

- Punching holes or slots in metal sheets

- Creating custom parts for machinery and equipment

- Producing decorative items like jewelry, signs, and art pieces

These applications highlight the machine’s ability to handle both large-scale production and small, detailed projects. Whether you’re working on an industrial scale or crafting a one-of-a-kind piece, a **laser cutter metal** can adapt to your needs.

Benefits of Using a Laser Cutter Metal

There are numerous reasons why businesses and individuals choose a **laser cutter metal** over traditional cutting methods. Let’s explore some of the key advantages:

Precision and Accuracy: The laser beam is incredibly precise, allowing for cuts as thin as 0.1 millimeters. This level of accuracy ensures clean, seamless results even on complex designs.

Speed and Efficiency: Compared to mechanical cutting methods, laser cutting is much faster. It can handle high volumes of work without sacrificing quality, making it ideal for industrial applications.

Minimal Material Waste: Since the laser only removes a minimal amount of material during the cutting process, there is little waste. This makes it an eco-friendly and cost-effective solution.

Versatility: A **laser cutter metal** can work with a wide range of materials, including stainless steel, aluminum, brass, and copper. It’s also capable of creating both simple straight cuts and intricate curved designs.

Maintenance and Safety Considerations

While a **laser cutter metal** offers numerous benefits, it’s important to consider maintenance and safety. Regular cleaning and calibration are essential to ensure optimal performance and longevity. Additionally, operators must follow proper safety protocols, such as wearing protective eyewear and ensuring adequate ventilation in the workspace.

Key Maintenance Tips:

- Clean the lens regularly to prevent dust or debris from affecting laser performance

- Inspect the machine for wear and tear on a routine basis

- Ensure proper cooling systems are in place to avoid overheating

Safety should always be a priority when working with laser cutting equipment. Proper training is essential to minimize risks and maximize efficiency.

Frequently Asked Questions About Laser Cutter Metal

If you’re new to the world of laser cutting, you might have several questions. Here are some common ones:

1. Can a laser cutter metal work on all types of metals?

While most **laser cutter metal** machines can handle a variety of materials, certain types of metal may require different settings or adjustments. For example, highly reflective metals like aluminum and copper can be more challenging to cut due to their reflectivity. Always consult the machine’s specifications before starting your project.

2. How easy is it to learn how to use a laser cutter metal?

Modern **laser cutter metal** machines are designed with user-friendly interfaces, making them accessible even for those with little experience. However, basic training or familiarity with CAD software is recommended to get the most out of the machine.

3. What types of projects are best suited for a laser cutter metal?

The **laser cutter metal** excels at creating detailed and precise cuts, making it ideal for projects that require intricate designs or complex patterns. It’s also suitable for high-volume production work where speed and consistency are crucial.

Choosing the Right Laser Cutter Metal

With so many options available on the market, selecting the right **laser cutter metal** can be overwhelming. Consider the following factors when making your choice:

Budget: Determine how much you’re willing to spend. Higher-end models often come with advanced features and better performance, but there are also cost-effective options for hobbyists or small-scale projects.

Material Thickness: The thickness of the metal you plan to cut will influence your choice of machine. Ensure the laser cutter can handle the maximum thickness required for your projects.

Additional Features: Look for features like automatic focusing, motion control, and software compatibility. These can enhance productivity and ease of use.

Tips for Maximizing Laser Cutter Metal Performance

To get the best results from your **laser cutter metal**, follow these tips:

1. Use High-Quality Materials: Invest in high-quality metal sheets to ensure clean cuts and professional-looking results.

2. Optimize Settings: Experiment with different settings to find the optimal combination of power, speed, and focus for your specific project.

3. Keep It Clean: Regularly clean the machine to prevent dust buildup, which can affect performance and reduce laser efficiency.

The Future of Laser Cutter Metal Technology

As technology continues to evolve, so does the **laser cutter metal** industry. Innovations such as higher-powered lasers, improved software interfaces, and automated systems are making these machines even more accessible and efficient. In the future, we can expect to see even greater advancements in speed, precision, and ease of use.

Conclusion

A **laser cutter metal** is a powerful tool that opens up endless possibilities for metalworking projects. Its precision, versatility, and efficiency make it an invaluable asset for businesses and hobbyists alike. By understanding its applications, benefits, and maintenance requirements, you can fully harness the potential of this cutting-edge technology.

If you’re ready to take your metalwork to the next level, consider investing in a high-quality laser cutter metal. With the right machine and some practice, you’ll be able to create stunning designs and durable parts with ease. Happy crafting!