“

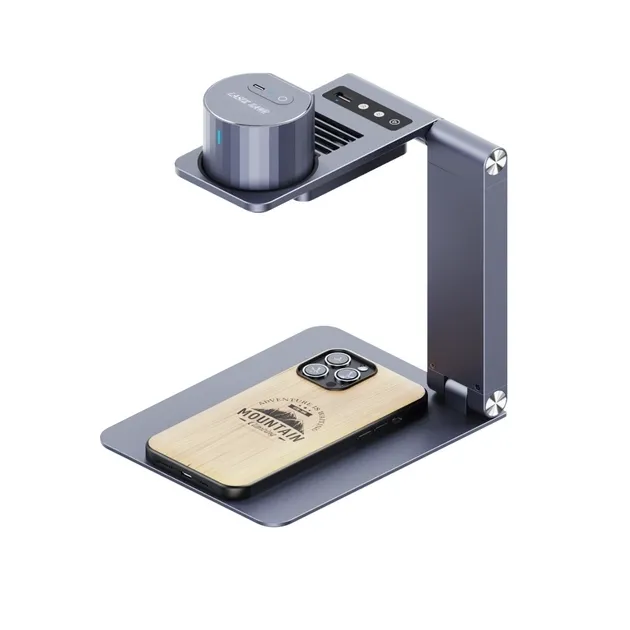

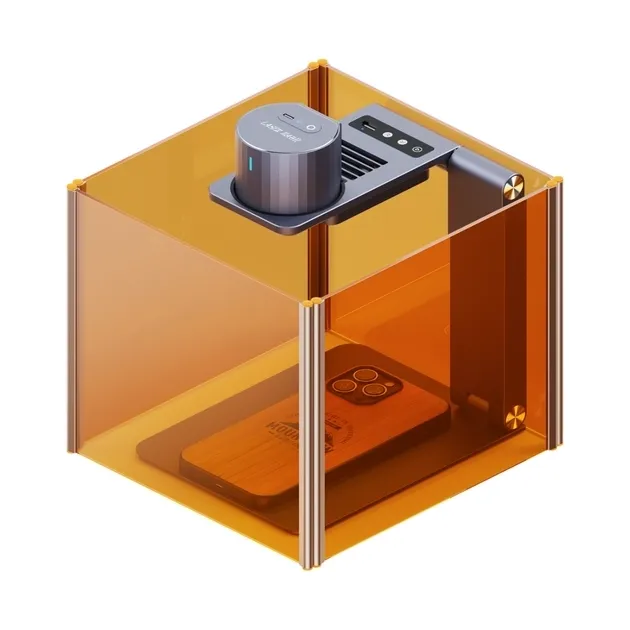

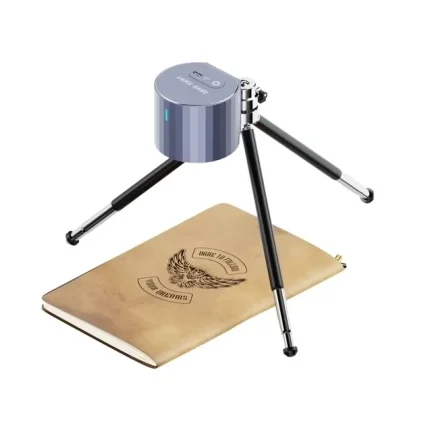

Introducing the LaserHawk LH1 Pro, the ultimate laser cutting and engraving machine designed for precision, versatility, and unmatched performance. Whether you’re a hobbyist, entrepreneur, or professional, this state-of-the-art machine is your gateway to limitless creativity and productivity.

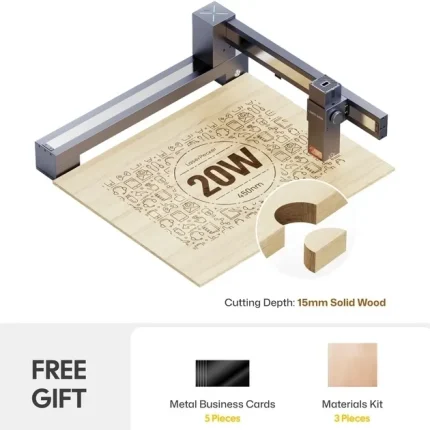

Equipped with advanced pmag engraving ir laser technology, the LaserHawk LH1 Pro delivers exceptional detail and speed, making it perfect for intricate designs, custom engravings, and high-quality cuts. From wood and acrylic to leather and metal, this machine handles a wide range of materials with ease, ensuring professional-grade results every time.

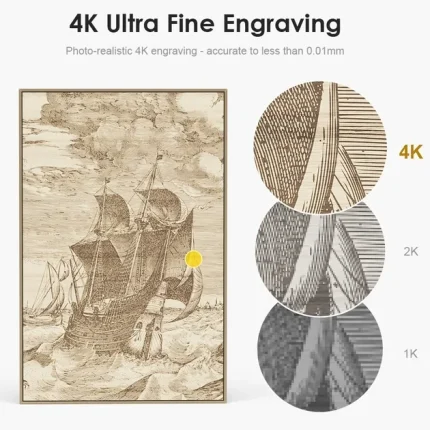

- Unmatched Precision: The pmag engraving ir laser ensures razor-sharp accuracy, allowing you to create intricate designs and fine details effortlessly.

- Versatile Applications: Whether you’re engraving personalized gifts, cutting intricate patterns, or prototyping designs, the LaserHawk LH1 Pro adapts to your needs.

- User-Friendly Design: With intuitive controls and a sleek interface, this machine is perfect for both beginners and experts.

- Durability & Reliability: Built with high-quality components, the LaserHawk LH1 Pro is designed to withstand heavy use while maintaining consistent performance.

Compared to competitors like the Glowforge laser engraver, the LaserHawk LH1 Pro stands out with its superior speed, precision, and affordability. It’s the ideal choice for anyone looking to elevate their crafting, prototyping, or small-scale production capabilities.

Transform your ideas into reality with the LaserHawk LH1 Pro – the ultimate laser cutting and engraving machine that combines innovation, performance, and value. Experience the future of laser technology today!

More you like:

Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5

Donald Wright (verified owner) –

**Laser Engraver Experience Review**

As an industrial designer, my experience with this laser engraver has been transformative across multiple projects. Here’s a concise overview of key aspects:

### 1. **Specific Project Experience**

– **Custom Signage**: I utilized the laser engraver for creating custom acrylic and metal signage. The precision allowed intricate details to be etched cleanly, ensuring vibrant and professional results.

– **Material Behavior**: Acrylic proved particularly responsive, with smooth engravings despite minor warping at higher power levels. Metal required careful power adjustments to avoid burn marks while achieving sharp contrast.

– **Challenges & Solutions**: For acrylic signs, heat-induced warping was a challenge. I mitigated this by using lower power settings and slower speeds, ensuring flat finishes without compromising detail.

### 2. **Technical Performance**

– **Power & Precision**: The engraver’s adjustable power range (10W to 40W) provided flexibility for various materials. At higher settings, it excelled in cutting through metal; at lower settings, it delivered fine engravings on wood and acrylic.

– **Software Experience**: The included software was user-friendly, with intuitive controls for adjusting laser speed, power, and focus. Integration with CAD files was seamless, though manual tweaking was sometimes needed for optimal results.

– **Special Features**: The multi-axis engraving capability allowed for creative 3D designs on cylindrical objects, expanding design possibilities.

### 3. **Business/Creative Impact**

– **Workflow Improvement**: The laser engraver significantly reduced post-processing time by minimizing imperfections and enabling precise cuts. This streamlined production from concept to finished product.

– **Customer Feedback**: Clients appreciated the high-quality finish, especially for custom signage and promotional items. One client highlighted the sharpness of engravings on metal as a standout feature.

### 4. **Comparison & Value**

– **Previous Tools**: Compared to manual engraving tools, this laser system offers greater precision and efficiency. It also outperforms older laser models in terms of speed and material adaptability.

– **Cost-Effectiveness**: While the initial investment was notable, reduced material waste and faster turnaround times have justified the expense. Recouping costs within six months through increased productivity.

– **Time Savings**: Projects that previously took hours now take minutes, freeing up time for new creative endeavors.

Overall, this laser engraver has been a reliable, versatile tool that enhances both creativity and efficiency in my design workflow.

Hiroshi Schmidt –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”