“

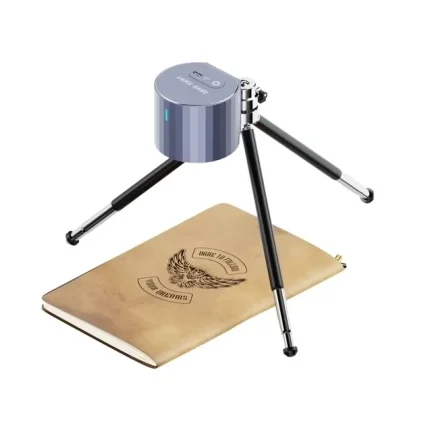

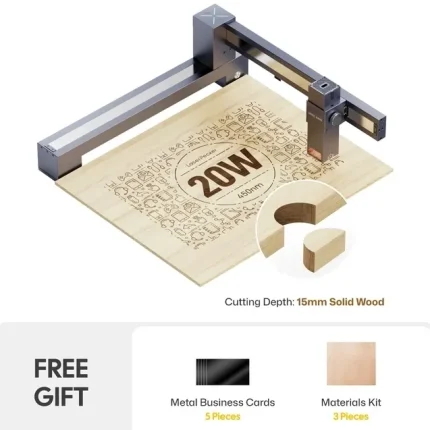

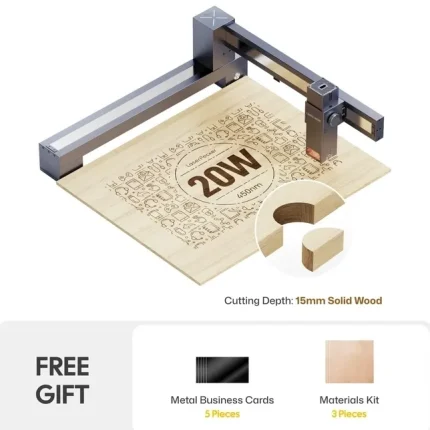

Introducing the LaserHawk LH3, a cutting-edge 3D printer and laser engraver that redefines precision and versatility in the world of laser technology. Designed for both professionals and hobbyists, this machine is your ultimate tool for creating intricate designs on a variety of materials, including metal, wood, and more.

The LaserHawk LH3 is not just a laser cutter machine for metal; it’s a multi-functional powerhouse that combines the capabilities of a 3D printer and a laser engraver. Whether you’re crafting detailed engravings on wood or cutting through metal with ease, this machine delivers unmatched performance and reliability.

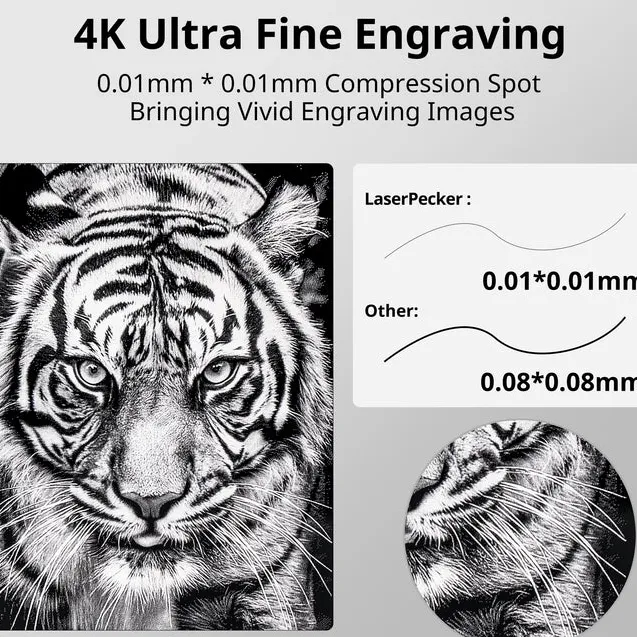

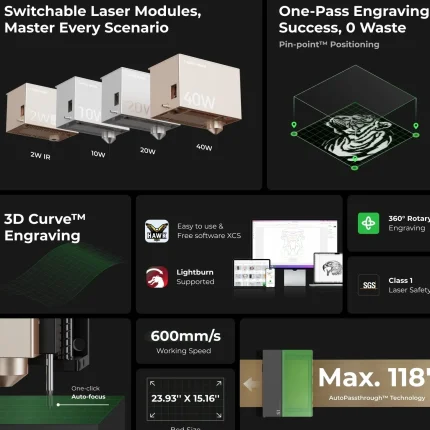

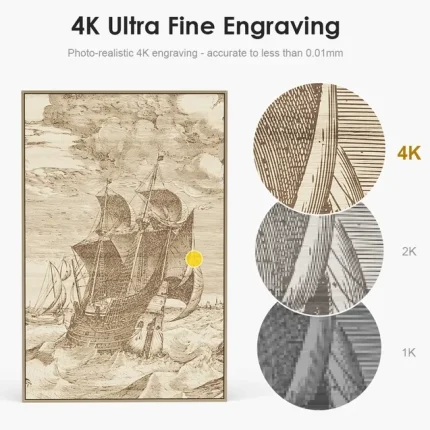

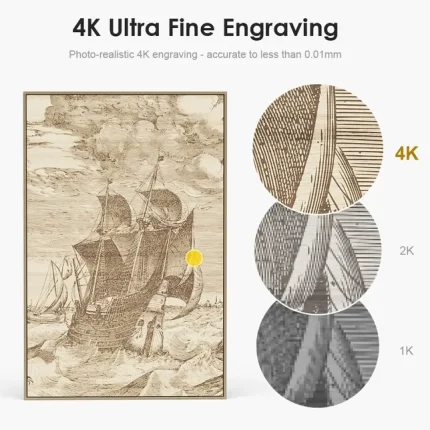

- High-Precision Fiber Laser: The LaserHawk LH3 features a state-of-the-art fiber laser that ensures precise and clean cuts on metal, making it the perfect laser cutter machine for metal.

- Versatile Material Compatibility: From wood to metal, this machine handles a wide range of materials with ease, making it the best laser engraver for wood and beyond.

- User-Friendly Interface: Equipped with an intuitive control panel, the LaserHawk LH3 is easy to operate, even for beginners.

- Compact and Durable Design: Built to last, this machine is compact yet robust, ensuring it fits seamlessly into any workspace.

- Advanced Safety Features: With built-in safety mechanisms, the LaserHawk LH3 prioritizes your safety without compromising on performance.

Whether you’re a professional looking for a reliable laser cutter machine for metal or a hobbyist seeking the best laser engraver for wood, the LaserHawk LH3 is your go-to solution. Experience the future of laser engraving and cutting with this innovative machine that combines the best of both worlds.

Transform your creative ideas into reality with the LaserHawk LH3 – where precision meets versatility.

More you like:

Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE

Francisco Hill (verified owner) –

**Industrial Designer’s Experience with Laser Engraver**

**Specific Project Experience: Custom Furniture Design**

In my recent project, I utilized the laser engraver to craft custom furniture pieces featuring intricate designs. The primary materials were wood and acrylic, chosen for their aesthetic appeal and engraving compatibility. A significant challenge was achieving consistent engraving depth across different materials. To address this, I conducted thorough testing on scrap material, adjusting power settings meticulously to ensure precision without burning.

**Technical Performance: Precision and Software Features**

The laser engraver’s technical capabilities were pivotal in the project’s success. Its adjustable power levels allowed for deep engravings in wood while maintaining fine details. The software provided a layering feature that enabled me to create 3D-like effects, enhancing the design’s depth and visual appeal. Additionally, the machine’s variable speed control was instrumental in adapting to different materials, ensuring smooth engraving processes.

**Business/ Creative Impact: Workflow Efficiency and Customer Satisfaction**

Incorporating the laser engraver into my workflow revolutionized how I approach custom projects. By handling production in-house, I reduced reliance on outsourcing, cutting costs and improving project turnaround times. The ability to produce intricate designs quickly allowed for more creative freedom and faster prototyping. Customer feedback was overwhelmingly positive, with appreciation for the unique and personalized touch, leading to increased client retention and new business opportunities.

**Comparison & Value: Cost-Effectiveness and Efficiency**

Compared to previous CNC machines, the laser engraver offered a significant advantage in both speed and precision. It halved production time for detailed work, enabling more iterations and refined designs. The initial investment was offset by long-term cost savings from reduced outsourcing and increased revenue streams from custom orders, making it a valuable asset to my business.

In summary, the laser engraver has been a transformative tool, enhancing both creative design capabilities and operational efficiency, while delivering exceptional customer satisfaction and economic benefits.

William Wagner –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”