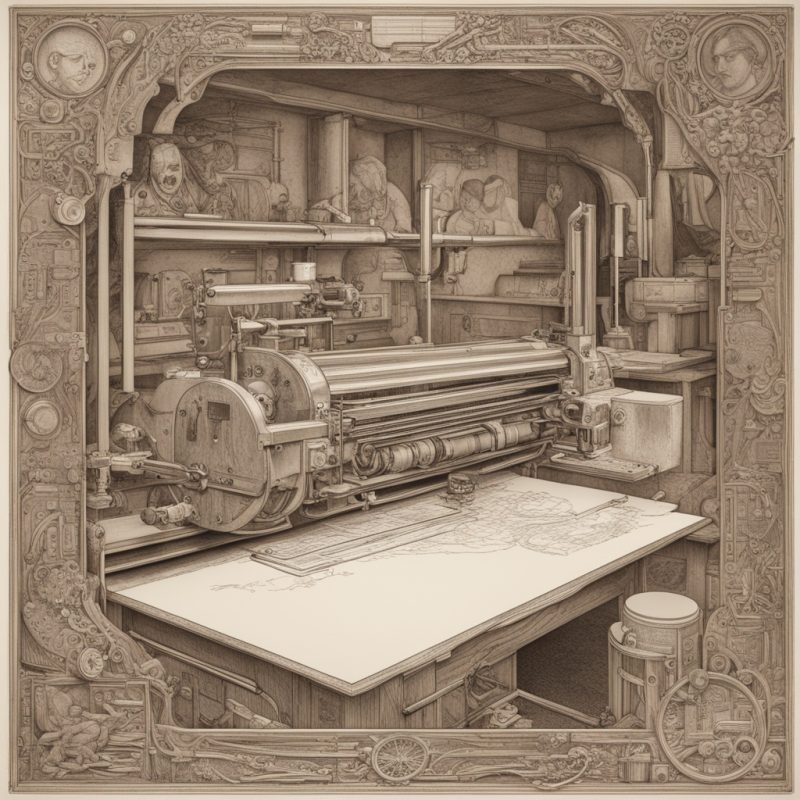

The Ultimate Guide to CNC Laser Cutter Steel: Revolutionizing Metal Processing

CNC laser cutting technology has become a cornerstone of modern manufacturing, offering precision, efficiency, and versatility in processing various materials, including steel. If you’re exploring the world of laser cutting, especially for metal fabrication, it’s essential to understand the capabilities and benefits of a CNC laser cutter steel machine. This article delves into everything you need to know about these machines, their applications, and how they can transform your production process. Let’s dive in!

What is a CNC Laser Cutter Steel?

A CNC (Computer Numerical Control) laser cutter steel is a machine designed to cut and engrave metal sheets with exceptional precision. Unlike traditional cutting methods, which rely on mechanical tools, this machine uses a high-powered laser beam to melt, burn, or vaporize the material. The process is guided by computer software, allowing for intricate designs and repetitive tasks to be executed with unparalleled accuracy.

The machine operates on the principle of directing a focused laser beam onto the surface of the metal. The beam’s intensity is so high that it can easily cut through steel sheets, leaving clean edges and minimal slag. This makes it ideal for industries such as automotive manufacturing, aerospace, construction, and artistic metalwork.

Why Choose CNC Laser Cutter Steel?

If you’re wondering whether to invest in a CNC laser cutter steel, here are some compelling reasons:

- Precision and Accuracy: The machine’s computer-guided system ensures that every cut is precise, minimizing material waste and enhancing product quality.

- Speed: Compared to traditional cutting methods, laser cutting is faster, reducing production time and increasing efficiency.

- Versatility: It can handle various materials, including steel, stainless steel, aluminum, and other metals, making it a versatile tool for multiple applications.

- Cost-Effective: Despite the initial investment, the machine’s long lifespan and low maintenance costs make it a cost-effective solution in the long run.

- Environmental Friendliness: Laser cutting produces minimal waste and emissions, making it an eco-friendly option for metal processing.

If you’re looking to streamline your production process or enhance your metal fabrication capabilities, a CNC laser cutter steel might be the perfect solution. But how do you choose the right one? Let’s explore this in the next section.

How to Choose the Right CNC Laser Cutter Steel

Selecting the right CNC laser cutter steel depends on several factors, including your specific needs, budget, and the scale of your operations. Here are some key considerations:

- Laser Power: The power of the laser determines its cutting capacity. Higher power lasers can cut thicker materials but may require more energy and maintenance.

- Cutting Speed: Consider the speed at which you need to process your materials. Faster machines are ideal for large-scale production, while slower ones may suffice for smaller operations.

- Material Thickness: Determine the maximum thickness of steel sheets you plan to cut. This will help you choose a machine with the appropriate laser power and cutting head.

- Software Compatibility: Ensure that the machine’s software is compatible with your existing design programs, such as CAD or CAM.

- Maintenance and Support: Look for machines with reliable customer support and easy access to spare parts. Regular maintenance can extend the lifespan of your equipment.

For those looking for a high-quality CNC laser cutter steel, consider exploring options available at [Your Website Name]. We offer a wide range of machines tailored to meet your specific requirements, ensuring you find the perfect fit for your operations.

Applications of CNC Laser Cutter Steel

The versatility of CNC laser cutting makes it suitable for a wide array of applications. Here are some common uses:

- Metal Fabrication: Cutting and engraving steel sheets for components in machinery, furniture, and decorative items.

- Automotive Industry: Creating intricate parts and components for vehicles with high precision.

- Aerospace: Manufacturing lightweight yet durable parts for aircraft and spacecraft.

- Construction: Cutting metal sheets for building structures, roofing, and other construction materials.

- Artistic Metalwork: Engraving intricate designs on metal surfaces for artistic purposes.

The applications of CNC laser cutter steel are virtually limitless, making it an invaluable tool for any industry that requires precise and efficient metal processing.

Maintenance Tips for CNC Laser Cutter Steel

To ensure optimal performance and longevity of your CNC laser cutter steel, follow these maintenance tips:

- Regular Cleaning: Keep the machine clean to prevent dust and debris from interfering with its operation. Clean the lens, mirrors, and other optical components regularly.

- Lubrication: Apply lubricants to moving parts as recommended by the manufacturer to reduce friction and wear.

- Calibration: Periodically calibrate the machine to ensure accurate cuts and maintain its precision.

- Software Updates: Keep the machine’s software updated to take advantage of new features and improvements.

- Operator Training: Ensure that operators are well-trained in using and maintaining the machine to prevent accidents and extend its lifespan.

By following these maintenance tips, you can maximize the efficiency and longevity of your CNC laser cutter steel, ensuring it remains a reliable tool for years to come.

Frequently Asked Questions

If you’re still unsure about whether a CNC laser cutter steel is right for your needs, here are some answers to common questions:

- Q: How thick can a CNC laser cutter steel cut?

A: The maximum thickness depends on the machine’s laser power. High-power machines can cut through steel sheets up to several inches thick.

- Q: Is it easy to learn how to use a CNC laser cutter steel?

A: While basic operation is relatively straightforward, advanced features may require training or experience. Many machines come with user-friendly interfaces and software to simplify the process.

- Q: What materials can a CNC laser cutter steel handle?

A: It can cut various metals, including steel, stainless steel, aluminum, and titanium, as well as some non-metals like acrylic and wood.

- Q: How much does a CNC laser cutter steel cost?

A: Prices vary depending on the machine’s specifications, brand, and features. High-end models can range from tens of thousands to hundreds of thousands of dollars.

If you’re ready to take your metal fabrication to the next level, investing in a CNC laser cutter steel could be the best decision for your business. With its precision, versatility, and efficiency, it’s no wonder why this technology is becoming increasingly popular across industries.

Where to Buy Your CNC Laser Cutter Steel

If you’re looking to purchase a CNC laser cutter steel, there are numerous options available in the market. However, not all machines are created equal. At [Your Website Name], we pride ourselves on offering high-quality laser cutting machines that meet the diverse needs of our customers. Whether you’re a small workshop or a large-scale manufacturing facility, we have the right machine for your operations.

To learn more about our products and how they can benefit your business, visit [Your Website Name] today. Take the first step toward enhancing your metal fabrication capabilities with a reliable CNC laser cutter steel!

Remember, when it comes to precision and efficiency, trust [Your Website Name] for all your laser cutting needs.