The Ultimate Guide to Engraving Laser: Transforming Plastic with Precision and Style

Engraving lasers have revolutionized the way we customize and personalize products. From intricate designs to bold patterns, these machines offer unmatched precision and versatility. If you’re looking to enhance your projects or start a new venture in laser engraving, this guide will walk you through everything you need to know about **engraving laser** technology, its benefits, applications, and how to choose the right equipment for your needs.

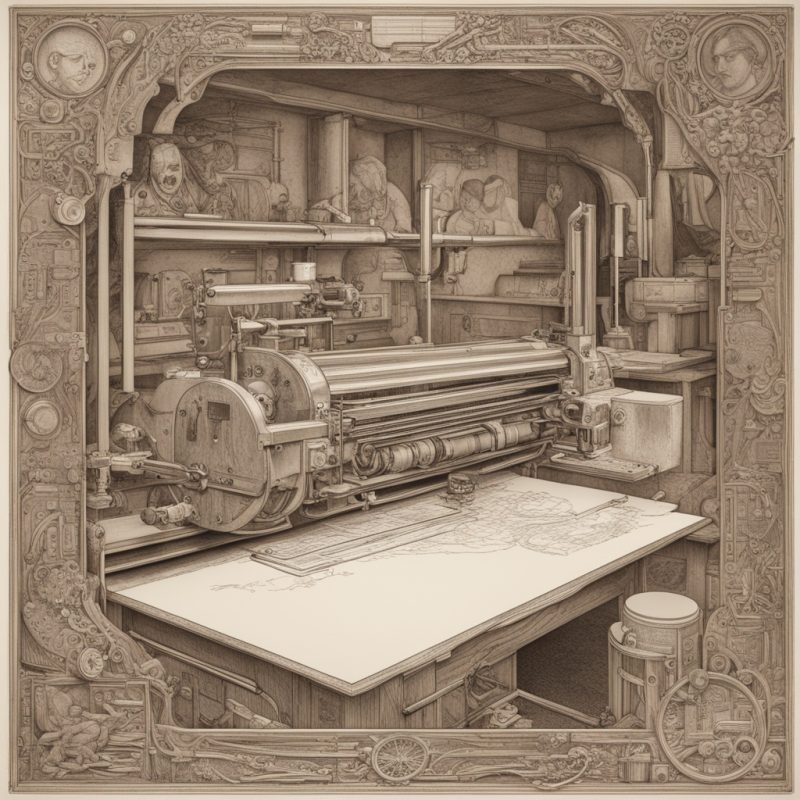

What is an Engraving Laser?

An engraving laser is a machine that uses focused light energy to or engrave materials such as plastic, metal, glass, and wood. Unlike traditional engraving methods, which often involve mechanical tools, **laser engraving** is a non-contact process. This means it doesn’t physically touch the material being engraved, reducing the risk of damage and increasing precision.

The technology behind laser engraving involves directing a high-powered laser beam at the surface of the material. The laser heats the material, causing it to vaporize or change color, leaving behind a precise and permanent mark. This method is ideal for creating detailed designs, logos, and text on various surfaces.

Why Choose Laser Engraving Over Traditional Methods?

Laser engraving offers several advantages over traditional engraving methods. Here are some of the key benefits:

- Precision and Accuracy: Laser beams can create intricate designs with extreme precision, making them ideal for complex patterns and text.

- Speed: Engraving lasers work quickly, reducing production time compared to manual or mechanical engraving methods.

- Versatility: These machines can engrave a wide range of materials, including plastic, metal, glass, and wood, making them suitable for various applications.

- No Physical Contact: Since the laser doesn’t physically touch the material, there’s no risk of scratching or damaging the surface.

- Durability: Laser-engraved marks are permanent and resistant to wear and tear.

If you’re considering investing in an **engraving laser**, these benefits make it a worthwhile choice for both small-scale projects and large-scale production. Whether you’re a hobbyist or a professional, this technology can elevate your work to new heights.

Applications of Laser Engraving

Laser engraving has countless applications across various industries. Here are some of the most common uses:

- CUSTOMIZATION: Personalizing items like jewelry, nameplates, and decorative objects with unique designs or text.

- PRODUCT IDENTIFICATION: Adding barcodes, serial numbers, or logos to products for branding and tracking purposes.

- ELECTRONICS: Engraving circuit boards or components with intricate details that are difficult to achieve manually.

- Medical Devices: Creating precise markings on surgical instruments or implantable devices.

- AUTOMOTIVE INDUSTRY: Adding custom graphics, logos, or identification numbers to car parts or accessories.

With the right equipment, such as the **engraving laser** available at [insert link], you can unlock these possibilities and more. Whether you’re working with plastic, metal, or another material, laser engraving offers a versatile solution for your needs.

How to Choose the Right Engraving Laser

Selecting the right **engraving laser** depends on several factors, including the type of material you’ll be working with, the level of precision required, and your budget. Here are some key considerations:

- MATERIAL COMPATIBILITY: Ensure the laser is compatible with the materials you plan to engrave. For example, some lasers work better with plastic than with metal.

- POWER LEVEL: Higher power levels are generally needed for thicker or harder materials, while lower power levels are sufficient for thin or delicate surfaces.

- PRECISION: Look for a laser with a high-resolution beam to achieve intricate and detailed designs.

- BUDGET: Consider your budget when choosing between different models. While higher-end lasers offer more features, there are also affordable options available that provide excellent results.

If you’re unsure which laser to choose, consult with experts or read reviews to find the best option for your specific needs. The **engraving laser** at [insert link] is a great starting point for those looking for high-quality equipment without breaking the bank.

Tips for Getting Started with Laser Engraving

If you’re new to laser engraving, here are some tips to help you get started:

- PRACTICE ON SCRAPS: Before working on your final project, practice on scrap material to get a feel for the machine and its settings.

- USE PROTECTIVE EQUIPMENT: Always wear safety goggles and ensure proper ventilation when using laser engraving equipment.

- START SIMPLE: Begin with basic designs or text before moving on to more complex patterns.

- EXPLORE SOFTWARE OPTIONS: Most **engraving lasers** come with compatible software for designing and controlling the machine. Explore these tools to unlock their full potential.

With a little practice and the right equipment, you can create stunning laser-engraved projects that stand out. The sky’s the limit when it comes to creativity!

Frequently Asked Questions About Engraving Lasers

Here are answers to some common questions about **engraving lasers**:

- Is laser engraving safe? Yes, as long as you follow safety guidelines and use protective equipment.

- Can I engrave all types of plastic? Most plastics can be engraved with a laser, but some materials may require specific settings or adjustments.

- How much does an engraving laser cost? Prices vary depending on the model and features, ranging from affordable options to high-end industrial machines.

- Do I need special training to use a laser engraver? While no formal training is required, familiarizing yourself with the machine’s operation and safety protocols is essential.

If you’re ready to take your projects to the next level, consider investing in an **engraving laser**. With its precision, versatility, and ease of use, this technology is sure to become a valuable tool in your arsenal.

Conclusion

Laser engraving has transformed the way we personalize and customize products, offering unparalleled precision and creativity. Whether you’re working with plastic, metal, or another material, an **engraving laser** can help you achieve stunning results. By considering your needs, budget, and project requirements, you can choose the right equipment to bring your ideas to life.

If you’re looking for a reliable and high-quality **engraving laser**, visit [insert link] today. Don’t miss out on this opportunity to elevate your projects and unlock new creative possibilities!