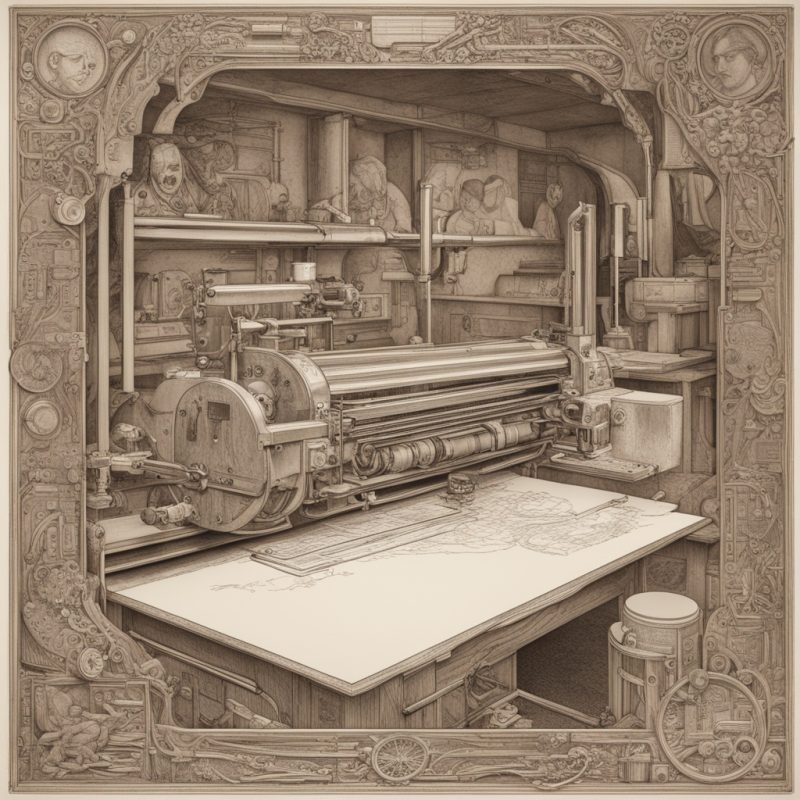

The Ultimate Guide to Laser Cutter and Engraver: Precision, Efficiency, and Creativity

Are you looking for a versatile tool that combines precision, efficiency, and creativity? Look no further than the **laser cutter and engraver**. This cutting-edge technology has revolutionized industries ranging from woodworking to metal fabrication, offering unparalleled accuracy and versatility. Whether you’re a hobbyist, an artist, or a professional, this article will explore everything you need to know about laser cutters and engravers, including their uses, benefits, and how they can transform your projects.

What is a Laser Cutter and Engraver?

A **laser cutter and engraver** is a machine that uses focused light beams (lasers) to cut, engrave, or mark materials with extreme precision. Unlike traditional cutting tools, lasers are non-contact, meaning they don’t physically touch the material being worked on. This minimizes wear and tear while delivering clean, seamless results.

The machine operates by directing a high-powered laser at the material, which vaporizes or melts it to create precise cuts or engravings. The process is controlled by computer software, allowing for intricate designs and patterns that would be difficult or impossible to achieve manually.

Types of Materials You Can Work With

One of the standout features of a **laser cutter and engraver** is its versatility. It can work with a wide range of materials, including:

- Wood

- Metal (steel, aluminum, brass)

- Plastics (acrylic, PVC)

- Paper and cardboard

- Glass

- Ceramics

Each material requires specific laser settings to ensure optimal results. For example, wood is often used for decorative engraving, while metal is ideal for industrial applications like cutting parts or creating custom signs.

Advantages of Using a Laser Cutter and Engraver

The **laser cutter and engraver** offers numerous advantages that make it a valuable tool in various industries:

- Precision and Accuracy: Lasers produce clean, precise cuts with minimal material waste. This is particularly important for intricate designs or projects requiring high tolerance levels.

- Speed and Efficiency: Modern laser machines can process materials quickly, reducing production time and increasing output. For businesses, this translates to cost savings and faster turnaround times.

- Versatility: As mentioned earlier, these machines work with a wide range of materials, making them suitable for diverse applications.

- Customization: Laser engraving allows for personalized designs, such as custom logos, text, or patterns. This is perfect for creating unique products that stand out in the market.

Applications of Laser Cutters and Engravers

The applications of a **laser cutter and engraver** are vast and varied. Here are some common uses:

- Furniture Making: Woodworkers use laser cutters to create intricate designs on furniture, decorative items, and custom cabinetry.

- Jewelry Design: Jewelers can engrave delicate details onto metal or stone, creating unique pieces with precision.

- Signage and Advertising: Laser cutting is ideal for producing signs, plaques, and promotional materials with sharp, professional finishes.

- Industrial Prototyping: Engineers use laser cutters to prototype parts quickly and accurately before moving to mass production.

Maintenance and Safety Considerations

While a **laser cutter and engraver** is a powerful tool, it requires proper maintenance and safety precautions to ensure optimal performance and longevity. Here are some tips:

- Regular Cleaning: Dust and debris can accumulate on the machine’s optics and surfaces, reducing efficiency. Regular cleaning with appropriate tools will help maintain performance.

- Lens Care: The laser lens is critical for focusing the beam. Avoid touching it directly and clean it only with specialized lens wipes or solutions.

- Safety Glasses: Always wear safety glasses when operating the machine to protect your eyes from laser exposure.

- Proper Ventilation: Laser cutting produces fumes, especially when working with certain materials. Ensure the workspace is well-ventilated or use a fume extraction system.

Frequently Asked Questions

If you’re new to laser cutters and engravers, you might have some questions. Here are answers to common queries:

- Q: Can I use a laser cutter on all types of materials?

A: While lasers can work with many materials, not all are suitable for laser cutting. Some materials may produce hazardous fumes or require specialized settings. Always consult the machine’s manual or manufacturer guidelines before working with new materials.

- Q: Is a laser cutter safe to use?

A: Yes, but only when used properly. Follow safety protocols, wear protective gear, and ensure the machine is operated in a well-ventilated area.

- Q: How much does a laser cutter cost?

A: The cost varies depending on the size, power, and features of the machine. Entry-level models can range from $500 to $2,000, while industrial-grade machines may cost tens of thousands of dollars.

Conclusion

A **laser cutter and engraver** is more than just a tool; it’s a game-changer for anyone looking to achieve precision, creativity, and efficiency in their projects. Whether you’re crafting custom furniture, designing jewelry, or prototyping industrial parts, this versatile machine can handle it all with ease. Invest in one today and unlock a world of possibilities!

If you’re ready to take the plunge, consider checking out our recommended models, including the X-Carve Pro Laser Cutter and the Epilog Helix Laser, which are perfect for both hobbyists and professionals. Start your journey into the world of laser cutting today!