The Ultimate Guide to Laser Cutter Engraver Machine: Precision, Speed, and Versatility

Laser cutting technology has revolutionized industries ranging from manufacturing to artistry. Among the most versatile tools in this field is the laser cutter engraver machine, which combines precision, speed, and creativity into one powerful tool. Whether you’re a professional artist, a hobbyist, or a small business owner, this machine can transform your projects with unmatched accuracy and efficiency. In this article, we’ll explore the features, applications, benefits, and considerations of using a laser cutter engraver machine. Let’s dive in!

What is a Laser Cutter Engraver Machine?

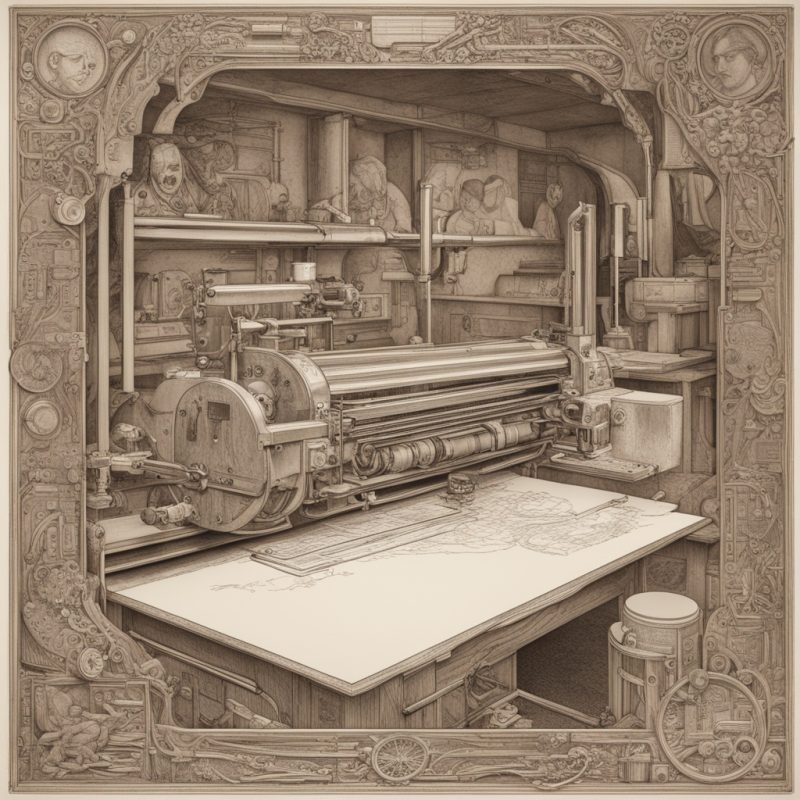

A laser cutter engraver machine is a multifunctional device that uses high-powered lasers to cut and engrave various materials. Unlike traditional cutting tools, which rely on physical contact, laser machines use light beams to create precise cuts or engravings. This non-contact method ensures minimal material damage and maximum accuracy, making it ideal for delicate or intricate designs.

The machine typically consists of a laser source, a control system, and a worktable. The laser source emits a focused beam that can be directed with extreme precision to cut or engrave materials such as wood, metal, plastic, glass, and fabric. The control system allows users to program and execute designs, while the worktable provides a stable surface for cutting or engraving.

Applications of Laser Cutter Engraver Machines

Laser cutter engraver machines are incredibly versatile and can be used in a wide range of applications. Here are some common uses:

- Cutting materials: From thin sheets to thicker materials, laser cutters can handle various thicknesses with ease.

- Engraving designs: Whether it’s a logo, pattern, or custom text, the machine can engrave intricate details with precision.

- Crafting jewelry: Laser cutting is perfect for creating delicate and precise pieces of jewelry.

- Prototyping: Quickly create prototypes for testing and design refinement.

- Sign making: Engrave custom signs, plaques, and name tags with professional-quality results.

- Fabric cutting: Laser cutters can be used to cut fabric for sewing projects or decorative purposes.

Benefits of Using a Laser Cutter Engraver Machine

Investing in a laser cutter engraver machine offers numerous benefits, making it a valuable tool for both professionals and hobbyists. Here are some key advantages:

- Precision and accuracy: Lasers provide exceptional precision, ensuring clean and precise cuts or engravings every time.

- Versatility: The machine can work with a wide range of materials, making it suitable for various projects.

- Speed: Compared to traditional methods, laser cutting is faster and more efficient, saving time and effort.

- Non-contact process: Since there’s no physical contact during the cutting or engraving process, there’s minimal risk of material damage.

- Creativity: With precise control over the laser beam, users can create intricate and complex designs that would be difficult to achieve manually.

- Cost-effective: While the initial investment may seem high, the machine’s durability and versatility make it a long-term cost-effective solution.

How Does a Laser Cutter Engraver Machine Work?

To understand how a laser cutter engraver machine works, let’s break down its components and processes:

- Laser source: The machine uses a laser source, typically a CO2 laser, to generate high-energy light beams. These beams are highly concentrated and can be directed with extreme precision.

- Control system: The control system consists of software and hardware that allow users to input designs, adjust settings, and execute the cutting or engraving process.

- Focusing optics: The laser beam is focused through a lens or mirror to create a pinpoint of intense light, which is then directed at the material being cut or engraved.

- Cutting or engraving: Depending on the settings, the machine can either cut through the material or create shallow engravings. The laser heats the material, causing it to melt, burn, or vaporize, leaving behind a clean and precise edge or design.

Choosing the Right Laser Cutter Engraver Machine

With so many options available in the market, selecting the right laser cutter engraver machine can be overwhelming. Here are some factors to consider:

- Budget: Determine your budget and prioritize features that align with your needs.

- Material compatibility: Consider the types of materials you’ll be working with, as not all machines are suitable for every material.

- Power output: Higher power lasers can cut thicker materials but may require more advanced safety measures.

- Software and controls: Look for user-friendly software that allows easy design input and customization.

- Size and portability: Consider the size of your workspace and whether you need a portable or stationary machine.

Tips for Using Your Laser Cutter Engraver Machine

To get the most out of your laser cutter engraver machine, here are some tips:

- Start with simple projects: Familiarize yourself with the machine’s capabilities by starting with basic designs and gradually moving to more complex ones.

- Experiment with materials: Test different materials to understand how they react to the laser beam and adjust settings accordingly.

- Maintain safety precautions: Always wear protective gear, ensure proper ventilation, and follow safety guidelines when operating the machine.

- Keep software updated: Regularly update your machine’s software to access new features and improvements.

- Clean and maintain the machine: Keep the worktable and optics clean to ensure optimal performance and longevity of the machine.

Frequently Asked Questions About Laser Cutter Engraver Machines

If you’re new to laser cutting, you might have several questions. Here are some common queries and their answers:

- Q: Can I cut metal with a laser cutter engraver machine?

A: Yes, but it depends on the type of laser and its power output. Higher-powered lasers are required for cutting thicker metals. - Q: Is laser cutting safe?

A: Yes, as long as you follow safety guidelines, such as wearing protective eyewear and ensuring proper ventilation. - Q: How much does a laser cutter engraver machine cost?

A: Prices vary widely depending on the model and features. Entry-level machines can start around $500, while professional-grade models can cost upwards of $10,000. - Q: Can I use a laser cutter engraver machine for DIY projects?

A: Absolutely! Many hobbyists and DIY enthusiasts use these machines for creating custom signs, jewelry, and decorative items.

Conclusion

A laser cutter engraver machine is a powerful tool that offers precision, versatility, and efficiency for a wide range of applications. Whether you’re creating intricate designs, prototyping products, or crafting custom items, this machine can take your projects to the next level. By understanding its features, benefits, and proper usage techniques, you can unlock its full potential and achieve professional-quality results. If you’re ready to elevate your creativity and productivity, it’s time to invest in a laser cutter engraver machine!