The Ultimate Guide to Laser Engraver and Cutter Machines

Laser technology has revolutionized industries by offering precise, efficient, and versatile solutions for cutting and engraving. Among these innovations, the laser engraver and cutter machine stands out as a game-changer. Whether you’re a hobbyist, artist, or business owner, this machine can transform your projects with its unmatched precision and versatility. In this comprehensive guide, we’ll explore everything you need to know about laser engravers and cutters, including their benefits, applications, and how to choose the right one for your needs.

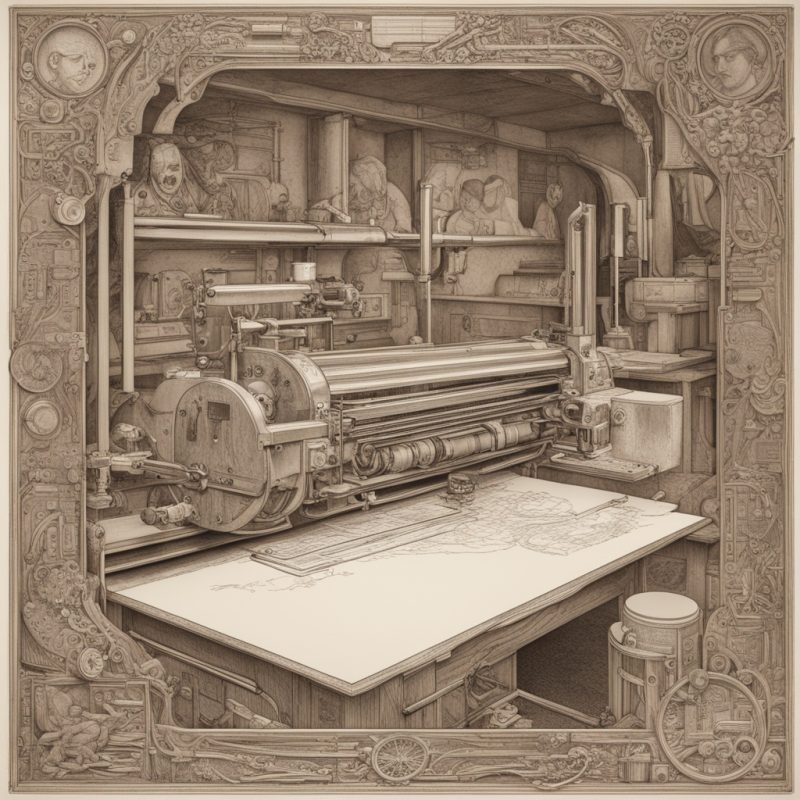

What is a Laser Engraver and Cutter Machine?

A laser engraver and cutter machine is a powerful tool that uses laser technology to etch, cut, or intricate designs onto various materials. Unlike traditional methods, this machine offers unparalleled precision, allowing users to create detailed patterns on wood, metal, plastic, glass, and more. The process involves directing a focused beam of light at high intensity to remove material layer by layer, resulting in sharp and polished finishes.

These machines are widely used in industries such as woodworking, jewelry making, advertising, sign-making, and even medical device manufacturing. Their ability to work with a variety of materials makes them an indispensable tool for both small-scale projects and large production runs.

Benefits of Using a Laser Engraver and Cutter Machine

Investing in a laser engraver and cutter machine comes with numerous advantages:

- Precision and Accuracy: The laser beam ensures that every cut or engraving is precise, even on the most complex designs.

- Versatility: It can work with a wide range of materials, making it suitable for diverse applications.

- Speed: Compared to traditional methods, laser cutting and engraving are much faster, saving time and increasing productivity.

- Durability: Laser machines are built to last, with minimal wear and tear over time.

- Eco-Friendly: They produce less waste and consume fewer resources compared to conventional cutting methods.

These benefits make the laser engraver and cutter machine a must-have for anyone looking to enhance their creativity or streamline their production processes.

How Does a Laser Engraver and Cutter Machine Work?

To understand how this machine works, let’s break it down into its basic components:

- Laser Source: The heart of the machine is the laser source, which generates a high-intensity beam of light.

- Focusing Optics: These lenses focus the laser beam onto the material, ensuring precise cutting or engraving.

- Motion System: The machine’s motion system moves the laser head accurately across the workpiece, following the programmed design.

- Control Software: Advanced software is used to design and control the cutting or engraving process, allowing for customization and precision.

The process begins by creating a digital design using compatible software. This design is then sent to the machine, which uses the laser beam to etch or cut the material according to the programmed instructions. The result is a finished product with exceptional detail and quality.

Applications of Laser Engraver and Cutter Machines

The applications of laser engravers and cutters are virtually limitless. Here are some of the most common uses:

- Woodworking: Create intricate designs, furniture parts, and decorative items with ease.

- Jewelry Making: Engrave delicate patterns on metals like gold, silver, and platinum.

- Signage and Advertising: Produce custom signs, logos, and promotional materials with precision.

- Fabrication: Cut and shape metal sheets for industrial applications.

- Crafts and Art: Allow artists to bring their designs to life on various materials.

These machines are also used in industries like electronics, automotive, and aerospace for creating precision parts and components. Their adaptability makes them a valuable tool across multiple sectors.

Choosing the Right Laser Engraver and Cutter Machine

Selecting the right machine depends on your specific needs and budget. Here are some factors to consider:

- Type of Material: Determine which materials you’ll be working with, as different machines are suited for different substrates.

- Budget: Laser engravers range from affordable hobbyist models to high-end industrial machines. Choose one that fits your budget while meeting your requirements.

- Size and Capacity: Consider the size of the projects you’ll be working on and choose a machine with the appropriate bed size and power output.

- Software Compatibility: Ensure the machine is compatible with the design software you plan to use.

If you’re unsure about which model to choose, consult with experts or read reviews to make an informed decision. Remember, investing in a high-quality machine will provide long-term benefits and better results.

Maintenance and Safety Tips

Proper maintenance and safety precautions are essential for maximizing the lifespan and efficiency of your laser engraver and cutter machine:

- Cleanliness: Regularly clean the machine to prevent dust and debris from affecting performance.

- Lens Care: Keep the focusing optics clean and free from scratches to maintain beam quality.

- Safety Gear: Always wear protective eyewear and gloves when operating the machine.

- Adequate Ventilation: Ensure proper ventilation to avoid inhaling fumes generated during the cutting process.

By following these tips, you can ensure safe and efficient operation of your laser engraver and cutter machine.

Frequently Asked Questions

Q: Can I use a laser engraver on all materials?

A: While most machines are versatile, some materials may not be compatible. Always check the manufacturer’s specifications before using new materials.

Q: How easy is it to learn how to use a laser engraver?

A: With user-friendly software and intuitive controls, even beginners can master the basics in no time. Tutorials and guides are widely available online.

Q: What are the maintenance costs for these machines?

A: Maintenance costs vary depending on the machine’s complexity. However, regular upkeep can reduce the need for costly repairs.

Conclusion

A laser engraver and cutter machine is a game-changer for anyone looking to elevate their projects or business operations. With its precision, versatility, and efficiency, it offers endless possibilities for creativity and production. Whether you’re a hobbyist, artist, or industry professional, investing in one of these machines can lead to remarkable results. So why wait? Explore the world of laser engraving and cutting today and unlock your full potential!